I. Product OverviewThe Textile Flatness Tester is a precision instrument designed to evaluate fabric

WhatsApp: +86 13816217984

E-Mail :info@qinsun-lab.com

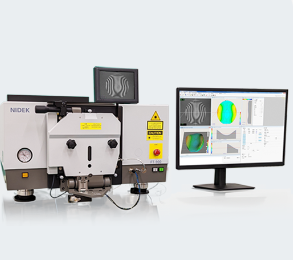

The Textile Flatness Tester is a precision instrument designed to evaluate fabric surface evenness by quantifying thickness variation, weave irregularities, and fiber distribution. It ensures compliance with quality standards for garment manufacturing, upholstery, and industrial textiles.

| Parameter | Specifications |

|---|---|

| Scanning Resolution | 0.1mm x 0.1mm grid mapping |

| Thickness Measurement Range | 0.05-10mm (±0.5% accuracy) |

| Surface Roughness Detection | 0.1-100μm Ra (ISO 4287 standard) |

| Light Source | 400-700nm RGB LED array |

| Datenausgabe | 3D topography map + statistical CSV |

| Dimensions | 1500×800×1200mm (L×W×H) |

Haftungsausschluss: Die oben genannten Inhalte dienen ausschließlich zur Referenz und Kommunikation zwischen Brancheninsidern und garantieren ihre Genauigkeit oder Vollständigkeit nicht. Gemäß den einschlägigen Gesetzen und Vorschriften und den Vorschriften dieser Website sollten Einheiten oder Einzelpersonen, die verwandte Gegenstände kaufen, gültige Qualifikationen und Qualifikationsbedingungen erhalten.

Unternehmen Telefon

+86-21-6420 0566

Arbeitszeiten

Montag bis Freitag

Handy:

13816217984

Email:

info@qinsun-lab.com