I. Definition und Arbeitsprinzip Digitale Schleifmaschine ist eine Laborausrüstung, die verwendet

WhatsApp: +86 13816217984

E-Mail :info@qinsun-lab.com

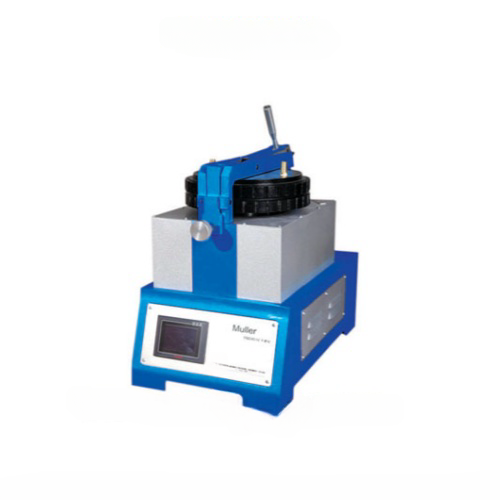

Der Müller Laboratory Grinder ist eine robuste Maschine, die ein optimales und perfekt reproduzierbares Schleifen und Dispergieren im Labor ermöglicht. Es wurde entwickelt, um kleine Mengen an Rohstoffen für Farben und Lacke zu schleifen und zu entladen.

Diese Einheit besteht aus einem Stahlrahmen, der zwei Mahlglasplatten hält, von denen die untere motorgetrieben ist. Ein LCD-Bildschirm kann dem Bediener helfen, die Gesamtzahl der Umdrehungen einzustellen und stoppt den Motor automatisch, sobald die vom Benutzer definierte Umdrehungsanzahl erreicht wurde. Darüber hinaus kann es auch die Gesamtzahl nach jedem Testzyklus anzeigen.

Eine Menge Rohstoff wird über einen begrenzten Bereich der unteren Glasplatte verteilt. Die Mischung wird in aufeinanderfolgenden Stufen, beispielsweise je 50 Umdrehungen, bei einem Druck von 445N gemahlen. Zwischen jeder Stufe sollte die Mischung innerhalb der begrenzten Fläche verteilt werden.

Müller Laboratory Grinder eignet sich zur Herstellung von Dispersionen zur Prüfung von Massenfarbe und Färbungsstärke sowie zur Herstellung kleiner Proben für die Qualitätskontrolle von Pigmenten

Es kann nach ASTM D 387 verwendet werden. ASTM D 332-B, ISO 8780-5.ISO 787/16.

GB/T 5211-16

GB / T 5211-19

GB/T 21867.1

GB/T 21868,5

ISO 787-16

ISO 787-17

nach ISO 8780-5

nach ISO 8780-1

Digitale Schleifmaschine ist eine Laborausrüstung, die mechanische Kraft verwendet, um Proben zu zerkleinern, zu mischen und zu schleifen. Sein Kernarbeitsprinzip nutzt Rotations- oder Vibrationskräfte, um die Probenfeinerung durch Kollisionen und Reibung zwischen Schleifmedien (z. B. Agatperlen, Glasperlen, Edelstahlperlen) zu ermöglichen.

Ausgestattet mit digitalem Anzeige- und Steuersystem für präzise Parametereinstellungen (z.B. Schleifzeit, Geschwindigkeit) und Echtzeitüberwachung.

Präzisionssteuerung: Die digitale Schnittstelle ermöglicht genaue Einstellungen für die Schleifdauer und die Drehzahl.

Multifunktionale Anpassbarkeit:

Kompatibel mit verschiedenen Schleifmedien (Agat/Perlen/Glas/Edelstahl)

Anwendungen umfassen Landwirtschaft, Lebensmittelwissenschaften, Biologie, Umweltwissenschaften und Mineralverarbeitung

Intelligente Automatisierung:

Überlastung/Überhitzungsschutz

Zeitgerechte Operation

Automatische Abschaltung

Wartungsfreundliches Design: Einfache Demontage- und Reinigungsmechanismen

Landwirtschaft: Kornverarbeitung, Ölsamenanalyse, Bodenprüfung, Tabakzubereitung

Lebensmittelindustrie: Futtermittelhomogenisierung, Käseverarbeitung, Fruchtpüreezubereitung

Biologie: Schleifen von Knochengewebe, Vorbereitung von Haarproben, Zellstörung

Umweltwissenschaft: Düngeanalyse, Recycling von Elektronikabfällen, Schlammbehandlung

Mineralmetallurgie: Legierungsverarbeitung, Kohlenbrechen, Erzraffinierung

Qinsun Instruments Co., LTD ist ein professioneller Laborprüfinstrumenthersteller in China, hat sich auf Laborinstrument R & amp; D konzentriert; D mehr als 30 Jahre und haben reiche Branchenerfahrung, basierend auf internationalen Teststandards, wir sind auch der Instrumentlieferant für BV SGS Labor, wir bieten One-Stop-Lösungen für Laborinstrumente, kostenlose Schulung und Schlüsselfertige Service, Produkte, die auf der ganzen Welt exportiert werden, bieten 36 Monate Garantie und sind ein vertrauenswürdiger Partner.

Unternehmen Telefon

+86-21-6420 0566

Arbeitszeiten

Montag bis Freitag

Handy:

13816217984

Email:

info@qinsun-lab.com